Content:

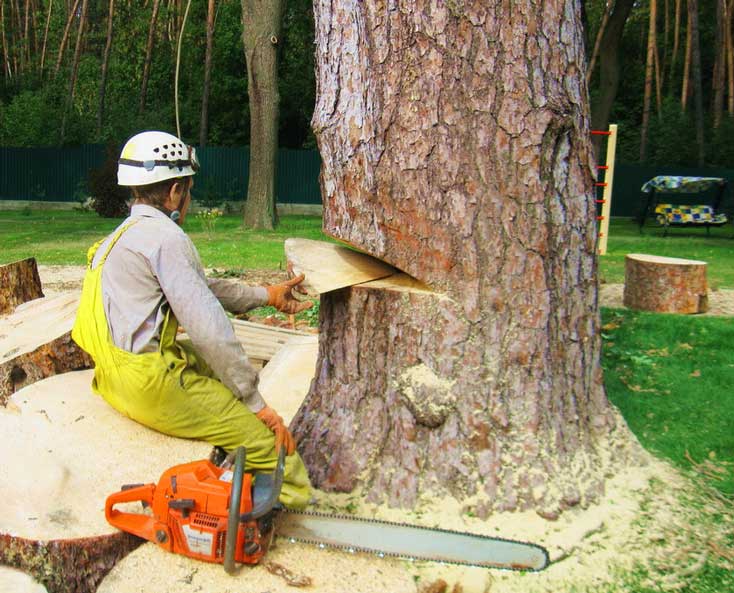

What tool has not been invented for working with wood! The usual hand saw was replaced by automated devices: disc, band, saber, circular. Each of them has its own working niche, that is, it is intended for a certain type of woodworking. Chainsaws combine many advantages and are ideally suited for a variety of tasks: from felling growing trees to sawing finished boards and squared beams. Depending on the type of machine that drives the saw chain, they are divided into

- gasoline;

- electrical.

Each of the types of this hand tool has a whole list of advantages, disadvantages and a huge army of fans who will defend the superiority of their favorite gasoline or electric unit. In such cases, a summer resident who acquires an assistant for work on the site will have to weigh all the arguments properly.

Features of the device of gasoline saws

The long and glorious history of chainsaw manufacturing has led to the standard of layout that has become a classic. Therefore, all devices offered by manufacturers will be assembled according to the same scheme.

Engine

The main difference that divides all owners into lovers of gasoline and electric current. Chainsaws use two-stroke engines. They have a single cylinder, air-cooled, like on motorcycles. This choice is due to the lighter weight, better torque and the ability to take more power from the same volume compared to the four-stroke, familiar to everyone in vehicles. The motor crankcase is made either entirely of metal or in combination with plastic. But even the use of alloys based on light aluminum is reflected in the solid weight of a gasoline saw.

Carburetor

In order to supply fuel to the combustion chamber of the working cylinder, mixed with air in the required proportions, a carburetor is used, as in the old Zhiguli. By the way, the famous Soviet saw "Druzhba" had a float - for this, the designers had to come up with a gearbox that allows the tire to be turned 90 degrees for horizontal sawing. In all modern saws, the carburetor is diaphragm, which allows you to work with the tool even upside down.

Fuel mixture

The simplified design of the two-stroke engine of the chainsaw does not contain either an oil pump or a pallet, therefore, to lubricate rubbing parts, oil is added directly to gasoline in a ratio from 1:25 to 1:50. The prepared mixture is not intended for long-term storage, therefore it is prepared in small quantities.

Ignition and starter

A spark for igniting fuel in the combustion chamber is given by a candle, and the voltage is supplied to it from an electronic unit, which is colloquially called magneto - the flywheel on the crankshaft gives it rotation. In order to initiate the launch, you need to pull the cable, sometimes several times.

Clutch

Since starting a gasoline engine is not an easy task, a clutch is provided for starting the saw headset. While it is off, the engine "turns" in idle mode. The clutch is centrifugal, it is triggered after the crankshaft spins to a certain number of revolutions. This allows not only to save fuel, but also to quickly stop the rotation of the drive sprocket when the saw bites or the chain breaks.

Distinctive features of electric chain saws

Engine

If in chainsaws the unit that drives the chain is the internal combustion engine, then in network devices this role is played by an AC motor. It can have brushes for supplying voltage to the armature or be brushless. The first design is simpler and cheaper, but requires periodic replacement of the brushes. But the second is devoid of disadvantages, except for the high price.

- The motor in the electric saw is quite powerful, heavy and voluminous. How it is located depends not only on the appearance of the saw, but also on other parameters:

- The transverse arrangement of the motor is structurally simpler, the saw is not so long, but wide - in a narrow opening this can interfere. The longitudinal arrangement of the engine without fail requires a transmission device - the design is heavier, but it is more convenient to work with such a saw, the body is narrow, nothing protrudes from it.

Drive unit

Since the acceleration and stop of the electric motor with one press of the control button, the clutch in the electric saws is often not provided. Only very expensive models can boast of this option. Most electric saws have a simple reduction gear. On units with a longitudinal engine, the rotor shaft torque is transmitted to the drive sprocket using a bevel helical gear.

Nutrition

In electric saws, there are two large classes of devices: mains and battery. The former are powered directly from an electrical outlet, the latter have a special pocket with connectors for installing a replaceable battery. The latter type is an attempt to overcome the lack of mobility of chain saws. However, the rather high cost of batteries and the limited resource of their operation makes such devices less popular than the classic ones with a cord and plug.

Common features of both types of saws

The main unit will remain unchanged, thanks to which the saw performs its direct functions - the saw headset. In the two types, it is almost identical, which allows for complete interchange.

Both petrol and electric saws require chain lubrication, for which a reservoir and a plunger pump with a gear drive from the clutch or from the gearbox are provided. It supplies the saw blade with a special liquid lubricant, which cools the chain and makes it easier to slip between the wood fibers.

The holding handles are also almost identical on both variants. The only difference is that in a chainsaw they are connected to the body and crankcase of the engine through shock-absorbing elements - springs and rubber dampers, and in electric saws this is not necessary, since the vibrations from the electric motor are minimal.

On a note! The chain tensioning mechanism for chainsaws is usually presented in the form of a screw in the front or on the side. Keyless chain tensioning is more of an option than a rule. But in power saws, the ability to tighten the chain without a nut is common on both cheap and expensive branded saws.

The advantages of gasoline chain saws

Gasoline-powered machines for sawing wood have a number of undeniable advantages that have led to their widespread distribution throughout the globe.

Autonomy

Here electricians will have to bow their heads in front of the internal combustion engine. The chainsaw is capable of working in any conditions, both 20 meters from home and two thousand. All that is needed for work is fuel and oil. Even cordless electric saws cannot be compared to gasoline devices in terms of their independence from power sources. After all, the battery will run out, and pretty quickly, and a can of gasoline will be enough for a whole day of work.

On a note! That is why the chainsaw cannot be replaced with an electrician for logging. Of course, for an ordinary non-professional summer resident there is no need to go so far and for a long time, but as a "car" saw for fishing trips or camping, the chainsaw is the clear leader. It is also a non-alternative option when erecting wooden buildings on a new site, where electricity has not yet been supplied.

Engine power and revs

Here the power tool will again have to surrender: the combustion engine is capable of delivering more power and torque. When it comes to working with large wood, and even for the preparation of firewood, the power tool runs the risk of overheating after 5 - 7 minutes of work under load. But raw, dry, or just solid wood will not leave a networked tool a single chance at all, even with a good headset. In addition, the speed and performance of the cut are affected by the high speed of the chain, and its wear remains almost unchanged.

Ability to work in a critical environment

Although this advantage is not the first priority, it is still worth mentioning for the sake of honesty. You can work with a chainsaw in the rain, put it in the snow, and she will have nothing. But with an electric saw, it's better not to do this - you can ditch the tool or cheer up from an electric shock.

Disadvantages of gasoline units

As in any popular tool, you can find many disadvantages in a chainsaw that will be inherent in the entire class of devices and not depend on the build quality.

Heavy weight

The margin of safety that has to be laid in the internal combustion engine in order for it to work for a long time turns into considerable weight. The ribbing of the cylinder, the piston, the crankshaft are all rather massive elements. Plus, the extra weight in the form of a gas tank filled with fuel doesn't make the saw lighter either. Compared to an electric saw of similar power, a gasoline unit will be 20 to 40 percent heavier.

Usage costs

In addition to replacing the chain and occasionally the tires, as well as adding chain oil, which is typical for both types of saws, devices with internal combustion engines are powered by a mixture of gasoline and oil. High-octane gasoline is used for modern saws, with a grade of at least 92. Ordinary engine oil will not work, you need a special two-stroke oil, which burns well and almost does not give soot. In terms of cost, good branded synthetics can surpass expensive automotive ones.

Consumables are also considered candles, a fuel filter, and on models with a felt version, an air filter. And although they do not need to be changed so often, this still increases the cost of use.

Skill

Any beginner who first picks up a chainsaw and tries to start it without prior knowledge and training is likely to fail. At the same time, he can be familiar with car motors along and across. The reason for this is the specific device of the chainsaw, to which you need to get used to.

The simplest startup sequence looks like this:

- put the saw on the brake;

- turn on electronic ignition;

- pump fuel with primer;

- pull out the choke lever, blocking it;

- pull the starter cord a couple of times until the saw "sneezes";

- push the shutter lever back;

- pull until the saw starts;

- remove from the brake;

- throttle - only then will the saw chain start to move.

If, in addition to this, the carburetor of the saw is not adjusted, the starting process turns into dancing with a tambourine and rumbling around the instrument. Starting in the cold will also add problems - this may require warming up the saw at room temperature.

Read also: How to adjust the carburetor on a chainsaw? Step-by-step instruction

Pluses of electric saws

Significant differences in the type of propeller make electric models competitive in the following indicators.

Sustainability

Here the owners of "gasoline" will have to use their hands. Their instrument smokes - and there's nothing you can do about it. And it's not even about protecting the environment. The exhaust gases are very useful for the operator himself. Therefore, only an electric saw is suitable for clean smokeless work. In closed rooms, you simply cannot do without it - in a room, garage or small hangar, it will not fill everything with the products of the burnt fuel mixture.

Cheapness

Apart from maintenance costs in order of the chain, the network version only consumes electric current and nothing else. And its cost in the vastness of Russia is still quite moderate. And although a powerful engine will spin the electric meter well, it will still cost less than all the components that power gasoline saws.

Ease of use

No additional buttons, toggle switches or shutters. I pulled the gas trigger and you can work. Let go - and the saw fell silent until the next start. Anyone can handle this. Therefore, women who use a chain saw in most cases choose the electric option - so as not to bother. Preparation for work is reduced to unwinding an electrical extension cord from the nearest outlet.

Cons of a power tool

Attachment to a current source

The weakest link is performance. Using such a saw further than 20 meters from the power source becomes problematic. Well, taking a saw with you on off-road pokatushki, picnic, fishing, on a hike is simply impossible. Does not add convenience and cable, always dragging on the operator. It constantly has to be shifted and paved, making sure that it does not fall under the chain, especially when it comes to sawing at a height or at an angle. Cordless saws only partially solve this problem, and they are much more expensive. And if you have to saw a lot and at the same time far? Then electricity is no longer remembered.

More modest performance

If the task is to clear the area of old trunks or deal with massive round timber by putting it on firewood, then you will need a powerful tool with a long tire. But where the chainsaw will cope without problems, the electric unit can slip, and this is fraught with a burnt out engine. In general, when operating under load, it is much more difficult and longer to overheat the piston than to burn the winding and cause an inter-turn circuit. Therefore, you will have to stop work to rest the instrument more often in the case of the network version. In addition, electric saws are not available with a busbar longer than 40 cm and a power higher than 2.7 kW.

| A controversial point. Sometimes they talk about the greater noise of a chainsaw compared to an electric one. In fact, the difference here is insignificant - only about 10 dB. Rather, we can say that the electric unit makes noise only in the active mode, and the gasoline one - even at idle, but it will still not work to work without interfering with others. |

Making a choice

Which tool to buy is a user's own business. It is only mono to give a rough outline of situations when the use of one or another type of saw will be more appropriate.

Who needs a chainsaw

Having brought together all the features, you can recommend a chainsaw for purchase if:

- you have a large plot and trees are scattered throughout the area;

- you need to cut not only on the territory, but also behind the fence

- you take the saw with you on a fishing trip, camping or just on the road;

- you are planning a construction site on a site without electricity;

- the material to deal with is thick trunks and hardwoods.

Dmitry, 42 years old, Chelyabinsk.

I'm for the chainsaw. I often take the instrument with me, I drive on dirt roads. It is easy to dissolve the tree blocking the road. I am generally silent about firewood. It helps if you get stuck - you can put a lever, make a lining under the wheel. Well, in the country, of course, he cuts everything that is needed. Well, refueling and starting up is a kind of ritual. There are no problems with the regulated carb.

When is it better to take an electric one

For those who have doubts, it is worth opting for a network tool if:

- the saw will be used rarely, from time to time;

- there is no need to harvest a large amount of firewood;

- you will have to saw small and medium-sized trunks, but mostly branches;

- all work will be carried out on the site, no further than 20 - 25 meters from the house or indoors.

Nikolay, 34 years old, Kursk.

Everyone advised a chainsaw, and I bought an electric one. Soberly figured, well, why do I need a chainsaw? I built a bathhouse - you only need to cut the board, timber and lining, they are quite thin, no power is needed. But I drink in the cold and in the heat. While working with something else, the saw just has time to cool down. Now I use it to care for the garden - quite enough, I see no reason to mess with the internal combustion engine.

Outcome

Each tool is good in its own way. In one, the low cost of operation attracts, in the other - autonomy. As experienced users aptly put it, a good owner should have both types of tools - this allows you to completely cover the need for working with wood.

The article uses materials from the portal aboutBenzopilah.ru